With

long industry experience and expert knowledge, we are known as one of the

leading roto seal coupling supplier, manufacturer and exporter in

India. Our superior quality roto seal couplings are made under supervision

of skilled and experienced professionals.

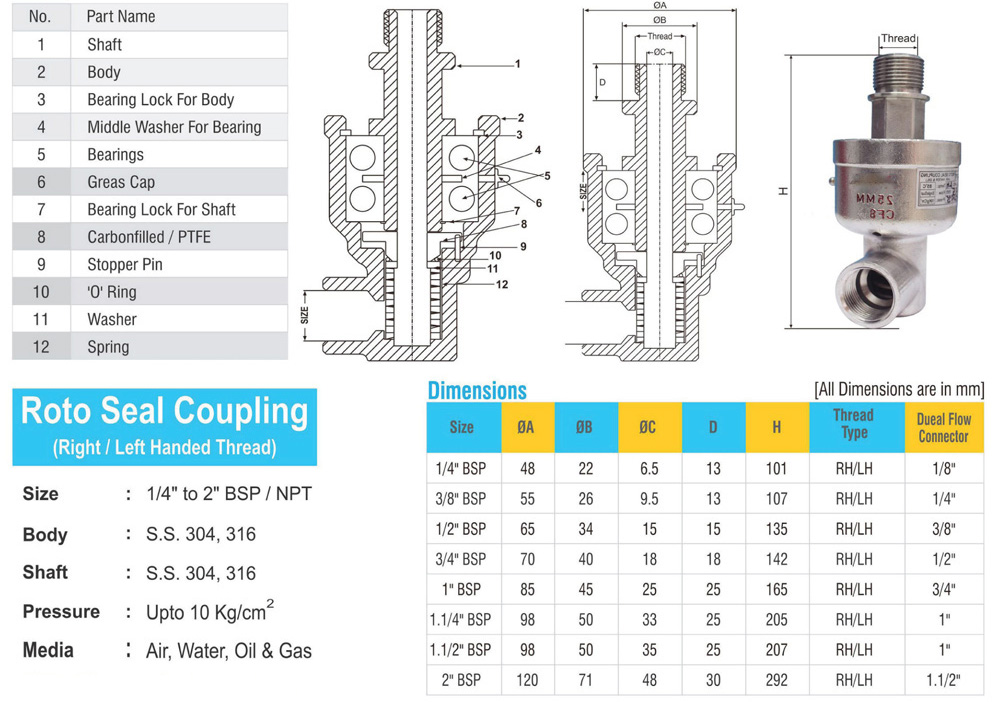

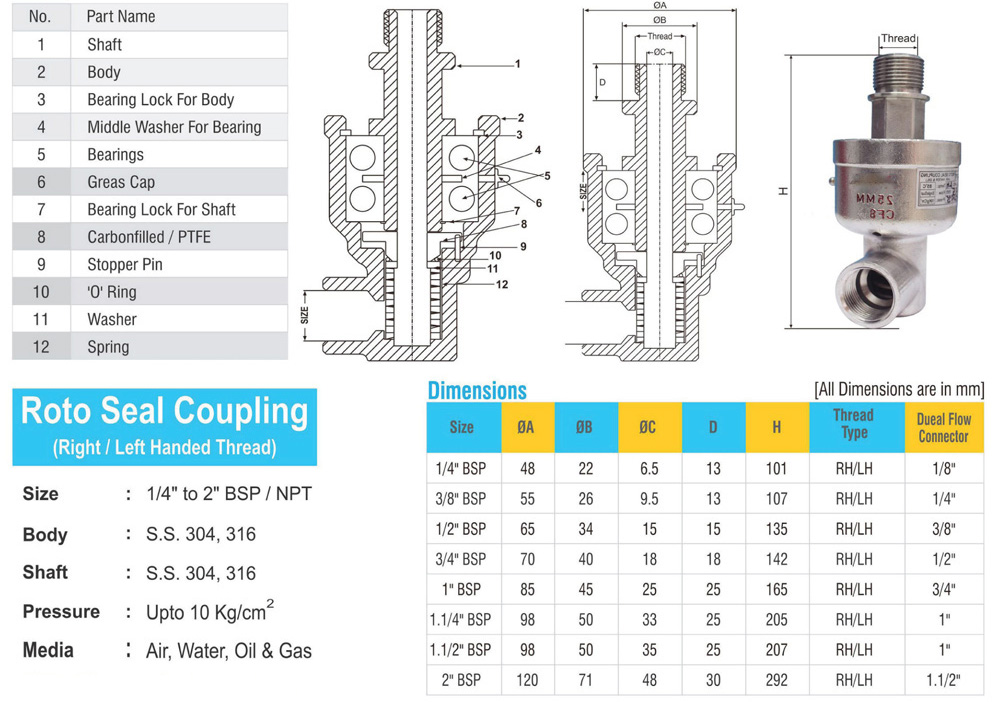

Roto Seal Coupling - Use of a Roto Seal coupling is

such a way that any fluid whether it is grease oil, thermal oil, coolants,

hydraulic fluid or mobile oil, can flow from one agent to another agent easily.

Roto Seal Coupling is a type of rotating joint which is used for allowing

rotation of parts that are united with each other. It is a kind of a device

which works as a seal between a stationery and a rotating instrument which make

the flow smoother & easier. Our Roto Seal Couplings are designed in a way

that fluids like, hydraulic fluid, coolants, thermal oil, grease oil can flow

with an ease between two agents.

Operation of Roto Seal Coupling - A roto seal coupling

locks the input valve during its rotation to meet an outlet valve. During the

movement, the fluid which could be either, gas or liquid will flow into roto

seal coupling from its source input and stored within the roto seal itself.

This fluid will release from the roto seal coupling when it meets with the

valve opening during rotation and more fluid will enter into the coupling for

next process. This coupling is designed such a way that it always rotates

around its axis and provides constant movement under high pressure. Design

of roto seal coupling varies as per the rpm, psi or number of

valves required. Roto Seal Coupling is used across industries such as

pharmaceutical, chemical, paper, food, plastic, steel, oil and many more.